ACME Electronics

At ACME Electronics, we lead the way in precision engineering and innovation as a prominent manufacturer and supplier of cutting-edge coil winding machines. With a relentless commitment to excellence and customer satisfaction, we have established ourselves as a trusted name in the industry.

Toroidal Winding Machines: Advanced Solutions for High-Precision Coil Production | ACME Electronics

In the field of coil manufacturing, toroidal coils are crucial components used in a variety of electrical devices, from transformers to inductors and filters. Unlike traditional solenoid coils, toroidal coils have a circular or donut-like shape, which makes them highly efficient and effective in reducing electromagnetic interference. To produce these coils with high precision, manufacturers rely on toroidal winding machines.

ACME Electronics

LVDT Coil Winders: Essential Solutions for Precision Winding | ACME Electronics

In the realm of precision engineering, especially when it comes to sensors like LVDTs (Linear Variable Differential Transformers, transformer winding machine), the role of coil winding is paramount. LVDTs are vital components in measurement systems, converting linear displacement into an electrical signal with high accuracy. To achieve this level of precision, it is essential to wind the coils used in LVDTs with accuracy and consistency.

ACME Electronics

Revolutionizing Coil Manufacturing with ACME Electronics Advanced Coil Winding Equipment

In the world of electrical manufacturing, coil winding equipment plays a pivotal role in producing coils that serve as the core components of countless electrical devices, especially transformer winding machines . Whether a transformer winding machine for transformers, motors, inductors, or sensors, the quality and accuracy of coil production directly impact performance and reliability.

ACME Electronics

Automating Your Winding Process with CNC Machines: Benefits and Considerations

In today’s fast-paced manufacturing landscape, automation has become a cornerstone for industries seeking increased efficiency, precision, and scalability. For companies involved in the production of coils, adopting automated solutions like CNC winding machines can revolutionize the winding process. Whether you’re producing electric motors, transformers, or inductors, transitioning to a CNC winding machine or an automatic winding machine can yield significant operational benefits. However, there are also important considerations to weigh before making the switch.

ACME Electronics

The Precision of CNC Winding Machines: Why Accuracy Matters in Coil Production

In the world of coil production, precision is paramount. As industries such as automotive, aerospace, electronics, and energy demand increasingly intricate and high-performance components, the importance of precision in the manufacturing process has never been more critical. Central to this evolution is the CNC winding machine, a technological marvel designed to deliver unmatched accuracy in coil winding. In this article, we’ll explore why precision matters in coil production, how CNC winding machines achieve it, and the benefits it offers to manufacturers.

ACME Electronics

Why Choose a CNC Winding Machine for Your Business: Key Benefits and Considerations

In the world of precision manufacturing, coil winding is a critical process that demands accuracy, consistency, and speed. For businesses that depend on the reliable production of coils — whether for electric motors, transformers, or inductors — choosing the right coil winding machine is essential. With advancements in automation and control technologies, CNC winding machines, automatic winding machines, and programmable winding machines have become the go-to solutions for companies looking to optimize their production processes. For more details visit:

ACME Electronics

The Role of Coil Winding Machines in the Aerospace Industry

The aerospace industry is known for its exacting standards and the need for high-performance components. Among the key technologies enabling these advancements is the coil winding machine, a crucial tool for manufacturing the coils that power motors, actuators, and many other vital systems. From ensuring precision to meeting stringent reliability standards, coil winding machines are indispensable in the development of aerospace technology. In this article, we will explore the significance of coil winding in the aerospace sector, the specific challenges involved, and the innovations driving progress in this field. For more details visit:

ACME Electronics

Coil Winding for Electric Motors: Exploring Advanced Techniques

Electric motors are at the heart of countless applications, from industrial machinery to electric vehicles (EVs). But the performance and efficiency of these motors largely depend on one crucial component — coil winding. The way coils are wound can significantly impact the motor’s energy efficiency, durability, and overall performance. As technology evolves, so do the methods used to wind coils, with advancements that push the boundaries of motor efficiency. In this article, we’ll explore how advanced winding techniques improve motor efficiency, reduce energy loss, and meet the specific needs of various motor applications, particularly in the automotive and industrial sectors.

ACME Electronics

Comparing CNC Winding Machines and Traditional Coil Winders: Making the Switch for Efficiency

In the world of coil manufacturing, precision, speed, and efficiency are paramount. Whether producing coils for electric motors, transformers, or inductors, the winding process plays a crucial role in the overall performance of the final product. Traditional coil winders have served the industry for decades, but with the rise of advanced CNC (Computer Numerical Control) winding machines, manufacturers are now facing the opportunity to revolutionize their production processes.

ACME Electronics

Toroidal Winding Machines - High Precision Solutions

Acme Electronics presents a versatile selection of toroidal winding machines, available in both belt and slider types, designed for high-speed programmable toroid core winding.

ACME Electronics

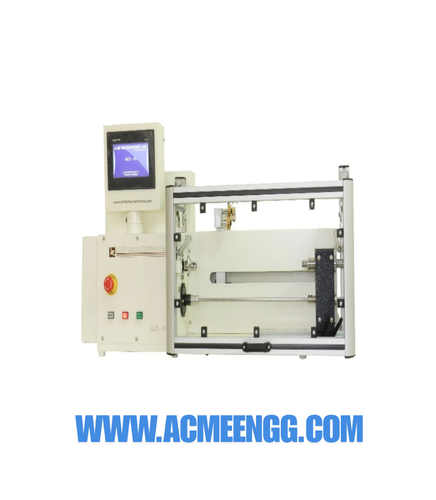

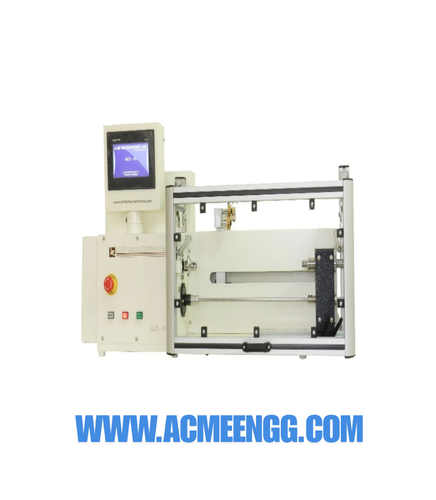

Linear Winding Machines - Precision & Versatility | Acme Engg

Acme Electronics offers a diverse range of 15 standard linear winding machine models, each designed to meet specific winding needs with precision and flexibility. Our machines are further customized to accommodate unique requirements, categorized into different series based on motor types and control systems. Among these, the AEX and AEH series stand out as our most versatile solutions, covering nearly 50% of coil winding applications.

ACME Electronics

Understanding Toroidal Winding Machines: Types, Features & Applications

ACME Electronics

Understanding Linear Winding Machines: Features, Types & Applications

Winding machines are in high demand due to their integral role in manufacturing essential electronic components such as resistors, capacitors, and inductors. These components are crucial for building any electronic circuit, with inductors specifically relying on winding machines for their production. Inductors, also known as coils, are fundamental components in electronics.

ACME Electronics

Motor coil Winding Machine Manufacturer Supplier | ACME Electronics

ACME Electronics stands as a premier manufacturer and supplier of Motor Coil Winding Machines. Our cutting-edge machines are designed to streamline your production process with programmable settings for up to 16 consecutive coils. This advanced feature ensures precision and efficiency, allowing you to produce a wide range of motors with consistent quality. Whether you require small or large-scale production, our Motor Coil Winding Machines offer the flexibility and reliability you need to meet your manufacturing demands.

ACME Electronics

Transformer Winding Machine Manufacturer Supplier | ACME Electronics

ACME Electronics stands as a prominent manufacturer and supplier of Coil Winding Machines in India, specializing in the design and production of cutting-edge Transformer Winding Machines. Our expertise spans a wide range of transformer sizes, catering to diverse needs from small-scale applications requiring a few VA to high-capacity transformers operating in the KVA range.

ACME Electronics

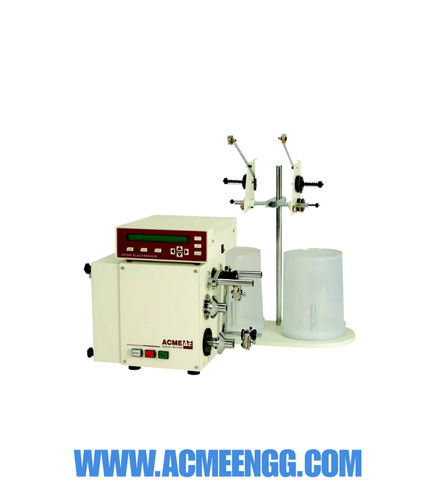

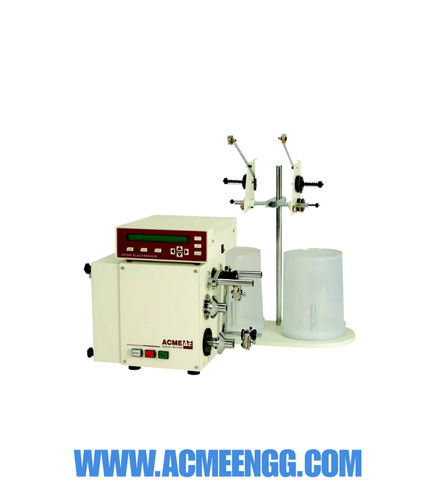

Toroidal Winding Machines - High Precision Solutions

ACME Electronics manufacturer supplier of Toroidal Winding Machines. Discover versatile Toroidal Winding Machines for precise coil winding needs. Get in touch today to customize your solution!

ACME Electronics

Coil Winding Machine | Automatic Winding Machine | Transformer Winding Machine | CNC Winding Machine Manufacturer Supplier

Coil winding machines are essential for producing precision coils used in transformers, motors, and electronics. These machines ensure accuracy, efficiency, and consistency in winding wires of various sizes and shapes. With advancements in automation, modern Automatic Winding Machine cater to diverse industrial needs, offering enhanced speed and quality. Acme Electronics stands out as a trusted name, delivering innovative solutions in coil winding technology to meet evolving industry demands.

ACME Electronics

Understanding Toroidal Winding Machines: Types, Features & Applications

Explore the different types of toroidal winding machines, including belt, slider, and gear types Learn about their components, functions, and applications

ACME Electronics

Toroidal winding machine Manufacturer Supplier

A toroidal winding machine is designed to wind coils in a toroidal shape, which is commonly used in transformers, inductors, and chokes. These machines are highly specialized, as toroidal coils require precision to maintain uniform winding and minimize losses. A toroid winding machine ensures that the wire is wrapped evenly around the circular core, which results in a compact and efficient design ideal for applications requiring low electromagnetic interference. The key advantage of using a toroidal design is its ability to reduce size while improving electrical performance. ACME Electronics offers advanced toroidal winding machines that combine speed, precision, and versatility, making them perfect for high-quality production. With these machines, manufacturers can efficiently produce durable and reliable toroidal coils for a variety of industries, from electronics to renewable energy systems.

ACME Electronics